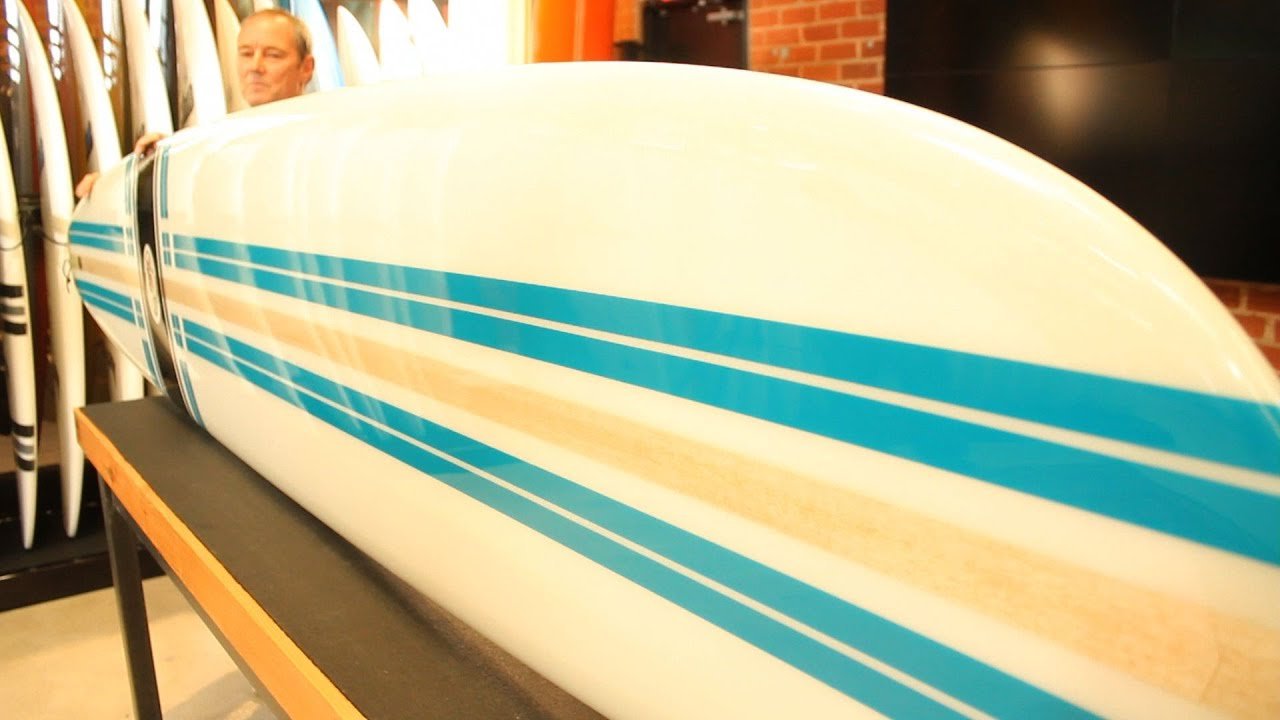

When choosing a board, you must consider the core construction material: Polyester (PU/Fiberglass) versus Epoxy. This choice influences everything from the board’s durability and cost to its flex pattern and feel in the water.

Key Takeaways & Tips

Epoxy Durability

Epoxy construction is significantly more durable than standard PU/Polyester. This durability makes it a great choice for longboards or standup paddleboards (SUPs) that you intend to keep for a long time.

Epoxy Flex

Epoxy boards surf more stiff and rigid. This lack of flex is a major difference compared to Polyester boards, which have more memory and spring in their flex pattern.

Polyester Flex

Polyester (PU) boards flex more and carry more memory in the flex pattern. This provides a different, often preferred, feel to the ride compared to the rigid nature of epoxy.

Cost

Epoxy boards are more expensive than PU boards, typically costing around $100 to $150 more due to the materials used.

Usage

While most people still use PU/Polyester, Epoxy has made a big leap in usage, particularly for longboards and SUPs, due to its enhanced durability.

Common Mistakes to Avoid

Ignoring Stiffness

Assuming all boards will flex the same. The stiffness of an epoxy board is its downfall if you prefer the classic flex pattern and feeling of a Polyester board.

Underestimating Cost

Not budgeting for the extra cost of epoxy construction. While durable, the price difference can be significant for entry-level buyers.