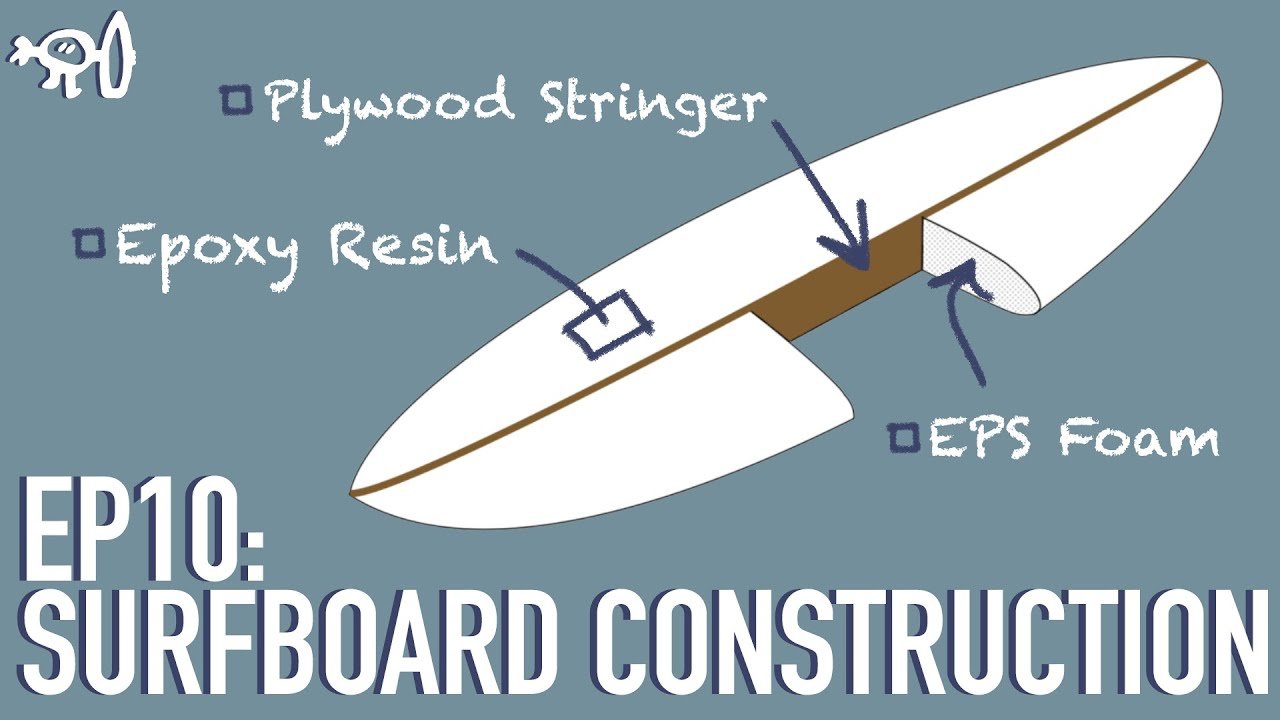

Understanding surfboard construction, from the foam core to the resin skin, is crucial for selecting the right board. This tutorial breaks down the qualities of standard Polyurethane (PU) and Expanded Polystyrene (EPS) foam cores, and the Polyester and Epoxy resins used to glass them.

Key Takeaways & Tips

Stringer Purpose

The stringer (wood strip) runs the length of the board to prevent the board from snapping by increasing strength and rigidity. Its weight is low, but it’s essential for determining the board’s flex pattern.

PU Foam (Standard)

Polyurethane foam has been the standard since the 50s due to its ease of shaping. Problem: Low compressive strength (causes pressure dings), absorbs water if dinged, and is environmentally toxic (nasty chemicals, takes 100,000 years to break down).

EPS Foam (Lighter & Stiffer)

EPS foam is stiffer and lighter (1–2 lbs/cubic foot), dramatically lightening the board. Benefit: Stronger, more recyclable, and more eco-friendly. Problem: Difficult to shape, and the beads can take on water if not properly fused/glassed.

Polyester Resin

Polyester is the traditional resin: cheap, quick, and easy to work with. Drawbacks: The hardening agent is toxic, it’s smelly, causes cosmetic yellowing, and cannot be used on EPS foam (it melts it).

Epoxy Resin

Epoxy is superior: it has higher impact resistance, doesn’t degrade (yellowing is cosmetic), and bonds better to the core (reducing delamination). Drawbacks: Slower drying process (requires climate control) and is 3–4 times more expensive than polyester.

Glassing Efficiency

Adding layers of fiberglass is an incredibly efficient way to increase strength. For every additional layer of cloth, there is a 300% increase in strength and stiffness with only a 25% increase in the weight of the board.

Common Mistakes to Avoid

Ignoring Flex Variability

Assuming all stringers flex equally. The wood grain can stiffen the flex pattern in one area, making a board frustratingly unique and difficult to replicate.

Ignoring Water Absorption

Assuming core material won’t absorb water. Both PU and EPS can absorb water if the outer skin is compromised, though EPS is more notorious for it due to the gaps between beads.

Low Deck Strength

Failing to add extra layers of glass to the deck of the board. Since the deck receives the most stress, extra layers are needed here to increase strength and protect the core from pressure dings.